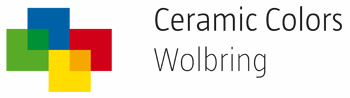

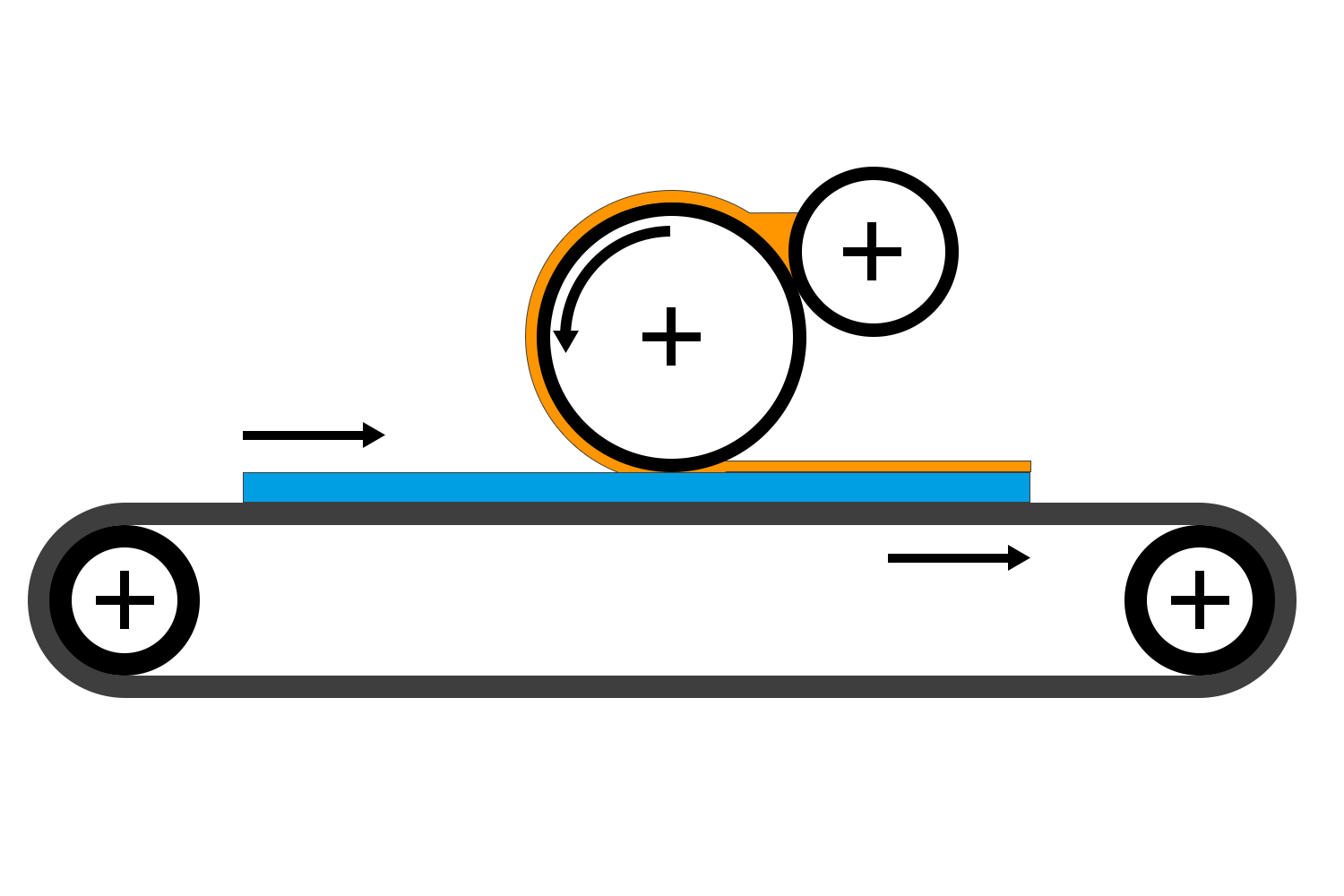

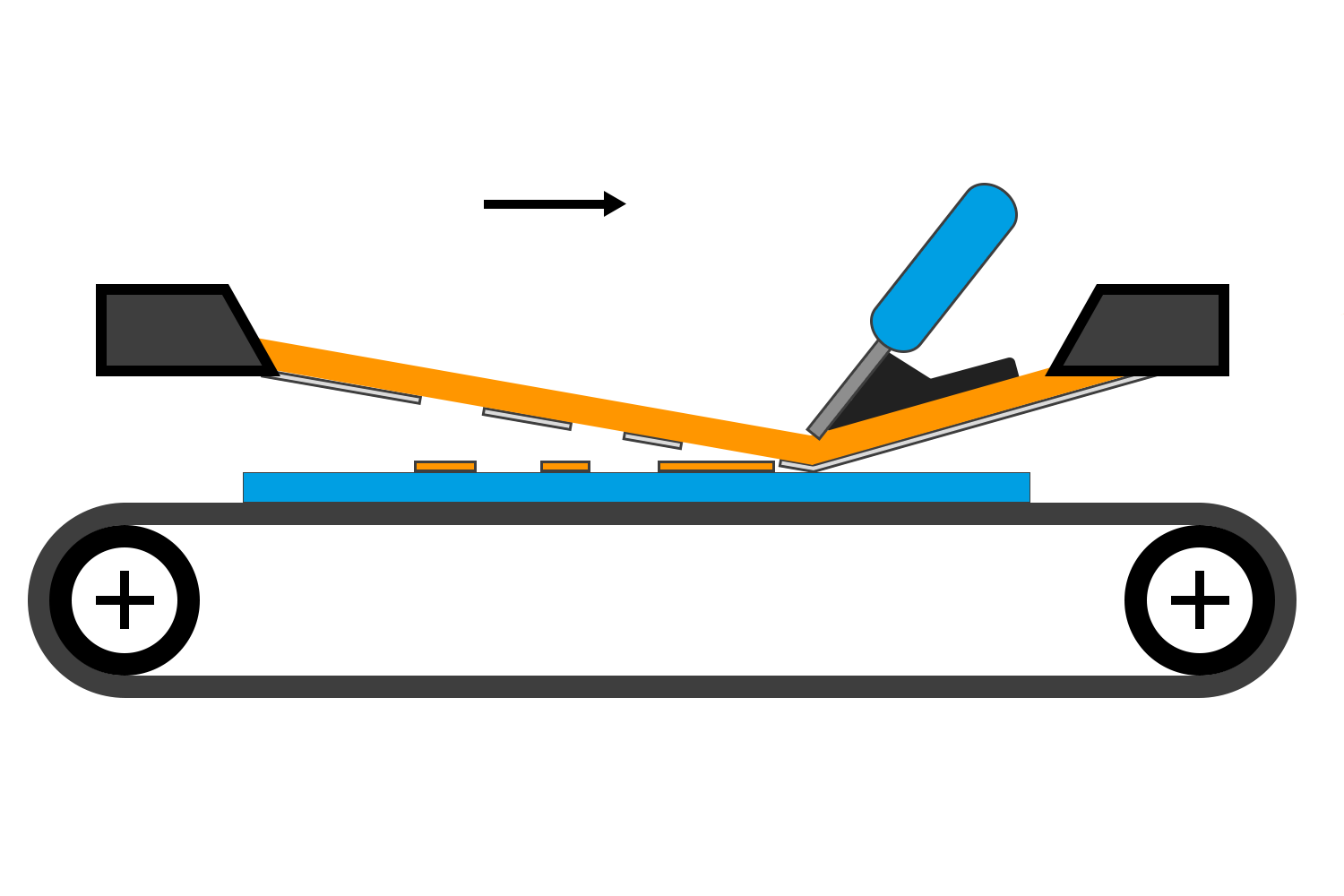

Processing techniques

A broad spectrum of techniques are available for processing the colours produced by Ceramic Colors Wolbring. Different techniques can be used depending on the application and the type of substrate. All the possible techniques are described in detail here. After this page, you can take a look at the different application possibilities and the appropriate processing technique in each case.